About

About Us

Gud Mould Industry Co., Ltd. is a professional manufacturer of plastic injection molding and die casting mould. Founded in 2007, Gud Mould Industry Co., Ltd. covers an area of 2500 square meters and has more than 100 experienced staffs, of which more than 30 with 20 years of experience in plastic engineering and die-casting.

To meet customers' higher requirements for product quality and greater demand for mould manufacturing, we constantly introduce advanced equipment, technology and talents at home and abroad to enhance our production means and technical support, constantly expand processing area to increase our production capacity. At present, Gud Mould has a large number of international advanced CNC machining centers, EDM, WEDM, milling machines, tool grinders and other precision die and mould processing equipment; imported spectrometers, metallographic analyzers, water capacity detectors, coordinate detectors, gauges and other international advanced detection equipment and instruments.

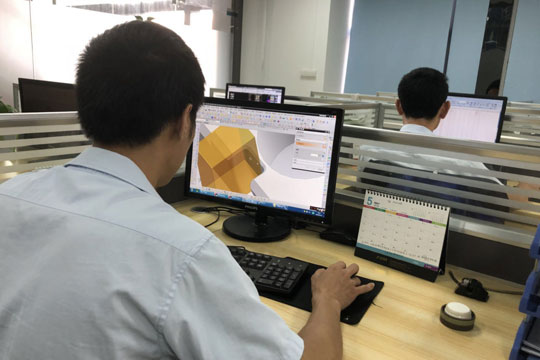

Gud Mould's die design and production all realize computerization, apply International advanced AutoCAD, Pro/E, UG, Cimatron, MASTERCAM, etc. File of IGS, DXF, STP, PORASLD and so on are acceptable here. After receiving drawings and data from customers, engineers of Gud Mould design and program first. Manufacture, produce and inspect them strictly according to drawings of mould engineering. All manufacturing processes realize digitalization of drawings, so as to ensure stability of high precision and high quality of dies. All materials of die are made of high quality steel and precision standard die base, which ensures service performance and life of die. In line with principle of customer first, we provide the best quality, delivery date, quality service and reasonable price, absolutely guarantee interests of customers, and provide confidentiality commitment to all technical information of customers.

Gud Mould Industry Co., Ltd. has always adhered to business philosophy of "people-oriented, quality first", and has been making progress and developing steadily. Although Gud Mould is medium-sized, it has been recognized by well-known domestic enterprises such as Chang'an, Changfei, Hafei, Lifan, Ford in China, and has established a good reputation among domestic customers. In 2018, we set up overseas department, which mainly develops overseas markets.

We sincerely welcome you to visit our company and expand your business!

Molding Design

1. Digitized Drawing - Converting three-dimensional product and die models into two-dimensional engineering drawings for conventional processing;

2. Digitized design of moulds: according to product model and design intention, relevant three-dimensional solid model of dies and moulds is established.

3. Digitized analysis and Simulation of mould-structure, thermal, fatigue and motion of die parts are carried out according to product forming process conditions.

4. Product forming process simulation-injection and stamping;

5. Customize standard parts and standard design process suitable for company's mould design;

6. Mould production management.

Professional software analysis and engineering evaluation are carried out for different structure and mould production in Gud Mould, reasonable structural requirements are synthesized, die structure is simplified, and technical review with customers is strengthened. Different inspection and review standards (e.g. photoelectric products, medical products, automotive products, etc.) are formulated according to different product areas to thoroughly understand design requirements. We conduct periodic evaluations to find the best way to reduce design cost of products or applications.

Quality Control

We have special inspection areas for raw materials, fittings and die holders to strictly control quality of all kinds of raw materials, including accuracy of various processing dimensions, material hardness and raw material analysis. 3D Coordinate Measurement, spectrometer, hardness tester and other measuring equipment are used to inspect and output results according to drawings and inspection standard process.

Through online MES and OA system, Gud Mould monitors quality of die process and pre-test spot inspection. Supported by abundant and effective measuring equipment resources and human resources, it controls every dimension and problem point of mould, and ensures delivery rate of mould is 100%.

We have a strict quality management system, and equipped with a number of high-precision testing equipment imported from Japan.

From production to delivery, quality control permeates every link. At the same time, we also have strict certification procedures for suppliers to ensure quality of raw materials and turnover materials.

Examination items include:

(1) Mould embryo detection.

(2) Steel testing.

(3) Inspection of standard parts of dies.

(4) Electrode detection.

(5)Inspection of in-house processed parts.

(6)Die inspection before shipment.

(7)Full-scale inspection of plastic products in.

Workshop

Mould Workshop

Injection Machine

EDM

CNC (3)

Painting Workshop

Packaging Workshop

Die Casting Workshop

Anodizing Workshop

Sample Room

R&D Center

Packaging Workshop

Mould Workshop 2